Decisive actor in Standardization

France Paratonnerres experts team is involved in National, European and International standardization comitees, thus demonstrating its permanent involvment in crucial areas of Standardization. These experts play an active role in Working Groups, Workshops, and participate to plenary meetings about several topics about lightning and E.M.F. Their in-depth expertise complete a strategic monitoring, which is then available for your information on relevant regulatory, strategic and economical evolutions.

Discover our main involvment in standardization Working Groups :

Working Groups

WG 11 : To prepare the serie of IEC 62561 standards

WG 12 : To prepare the standard for Lightning Location Systems (LLS)

WG 13 : To prepare the IEC 62793 Ed. 1 standard : Protection against lightning – Thunderstorm warning systems

Maintenance Team

MT 8 : IEC 62305-1 and -3 : Lightning Protection – Part 1 : General principles

MT 9 : IEC 62305-2 : Lightning Protection – Part 2 : Risk management

MT 14 : Standards revision for IEC 62561 standards

MT 15 : Standards revision for IEC 62561-5, IEC 62561-6 and IEC 62561-7 / Edition 1

UF 81 : French national comitee for lightning protection

CD 84 : French national syndicate for lightning protection GIMELEC – Strategic Division

CT 84 : French national syndicate for lightning protection GIMELEC – Technical Division

WG 02 : Lightning protection components – EN 50164 => EN 62561

WG 03 : Lightning protection

WG 04 : Damage risk analysis due to lightning – EN 62305-2

WG 05 : Lightning prevention devices – EN 50536

WG 06 : Performance of Lightning protection systems – EN 50622

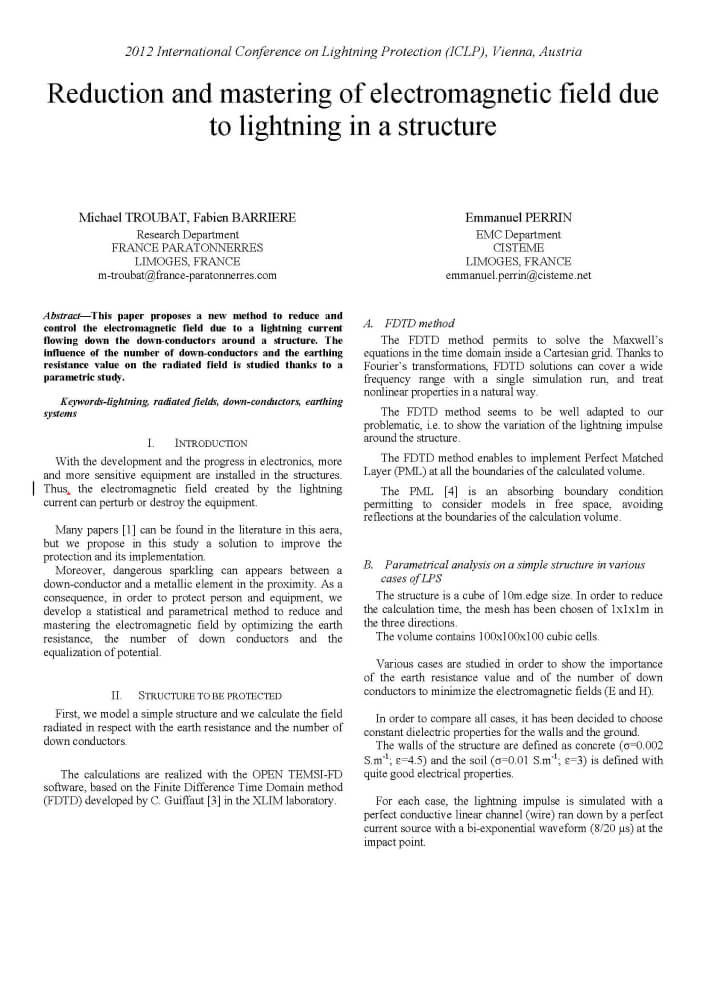

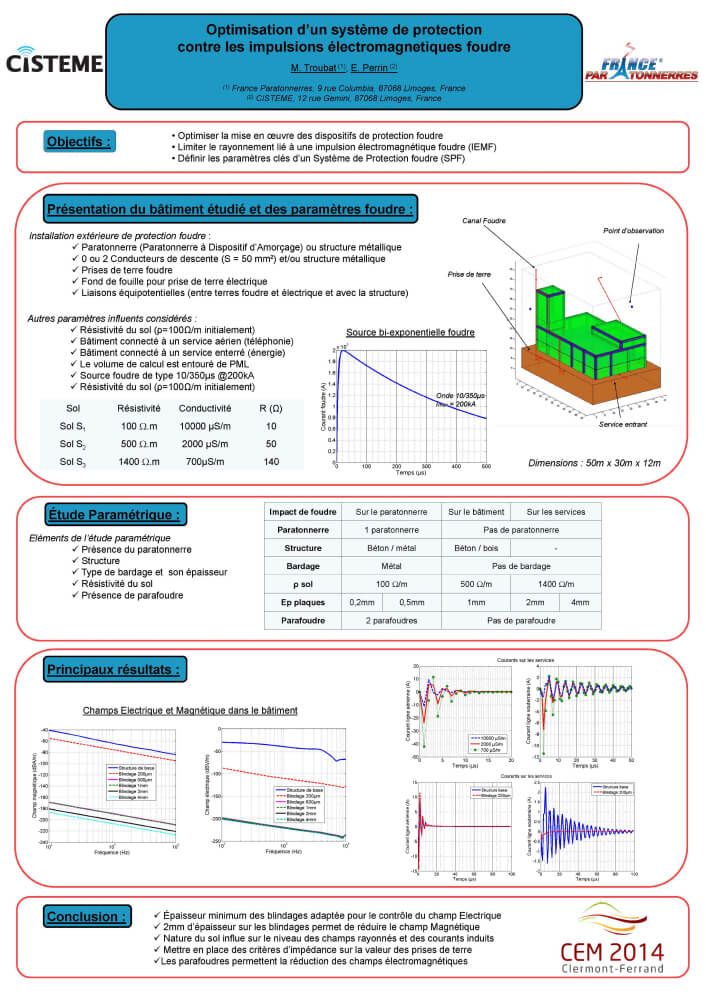

Our scientific publications

France Paratonnerres plays an active role in scientific research area with several collaborations with laboratories and renowned industrialists. Our commitment also extends to regular participation in various international congresses and conferences on lightning. We are proud to share the progress of our research, especially our collaboration with the C.N.R.S., during the presentation on the theme “Electromagnetic Field radiated by a lightning discharge and its impacts on a typical building“. This initiative demonstrates our constant quest for innovation and in-depth understanding of lightning-related phenomena, reinforcing our commitment to excellence in the field of lightning protection.

Electromagnetic field radiated by the lightning channel and its impacts on a typical building

Reduction and control of the electromagnetic field due to lightning in a structure

Optimization against electromagnetic lightning pulses

The Reliability and Effectiveness of the Advance Start Principle

ESE lightning rods performance

Rigorous tests in independent laboratories

Our Early Streamer Emission Air Terminals (Lightning rods) IONIFLASH MACH® NG have been subjected to rigorous tests, successfully meeting the most recent standards, in particular standard NF C 17-102 (2011). This comprehensive test sequence aims to guarantee the conformity and exceptional reliability of our products in varied climatic conditions.

During these tests, certain parameters were deliberately pushed beyond standard requirements, demonstrating the exceptional robustness and resistance of our IONIFLASH MACH® NG range. This more severe approach ensures optimal performance in real-world situations, taking into account the varied climatic conditions to which our devices will be exposed in the field.

The complete test sequence aims to simulate all possible conditions that our IONIFLASH MACH® NG ESE air terminals /lightning rods will encounter in situ. From resistance to extreme weather conditions to early streamer emission capability, every aspect is carefully evaluated to ensure reliable protection against atmospheric discharges.

By choosing our IONIFLASH MACH® NG air terminals, you are opting for products that have been subjected to in-depth testing, even exceeding standard standards, in order to offer you optimal protection in all situations. Our commitment to quality and performance is reflected in every step of the testing sequence, ensuring complete peace of mind for our customers.

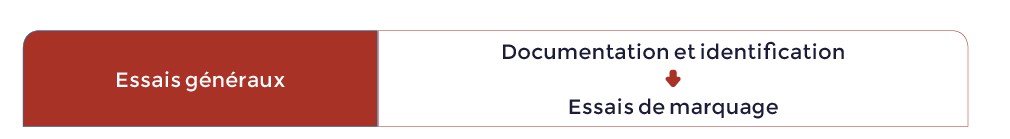

General tests :

The laser engraving of IONIFLASH MACH® NG suits to marking requirements of the test.

It is indelible over time.

Environmental tests :

The IONIFLASH MACH® NG passed with success the tests

• of aging in salt spray with a severity of Level 2 according to EN60068-2-52

• of aging in a humid sulphurous atmosphere with a sequence of 7 cycles, according to standard EN ISO 6988.

Efficiency tests :

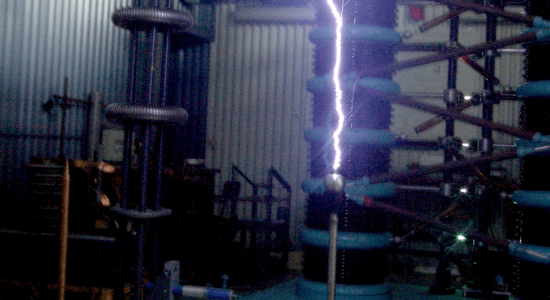

IONIFLASH MACH® NG air terminals are constructed to reduce the average statistical time associated with the emission of the upward leader. These ESEs present a gain in emission time compared to a simple rod lightning rod placed in the same conditions. This gain is evaluated in a high voltage laboratory.

Mechanical tests :

Continuous axis of IONIFLASH MACH® NG ESE air terminals through which the lightning current passes, has a minimum section of 200 mm² in accordance with the requirements of this test.

Electrical tests :

IONIFLASH MACH® NG, also demonstrated very good electrical and mechanical resistance during lightning breakdown by attachment in a 10/350 μs waveform at 100 kA.

After having undergone 2 series of 7 shocks at 100 kA (while the standard only requires 3 shocks…), one in negative polarity, and the other in positive polarity, the lightning rods show no indication of deterioration or perforation , with the exception of the parts carrying the lightning current where traces of ignition and fusion appear.

It is important to note that the electrical test was carried out on the IONIFLASH MACH® NG by the attachment method and not by contact.

and TESTS ABOVE STANDARD REQUIREMENTS

Complementary tests :

IONIFLASH MACH® NG passed also with success complementary tests, above standard requirements :

- INSULATION TEST in RAIN CONDITIONS according to 60060-1 : best efficient insulation on the market with a insulation greater than 97% for IONIFLASH MACH® NG lightning rods.

- 214 kA CURRENT TEST

In-situ, tests

for optimal protection

In situ testing of IONIFLASH MACH® NG Lightning Rods has been conducted in various climatic conditions and environments over time, demonstrating their exceptional strength and eficiency. Recently, we measured the performance gap at the Satu Mare church in Romania.

IN SITU TEST / SATU MARE CHURCH (ROMANIA) – 2024

Objective: Observe the early streamer emission of the IONIFLASH MACH® NG compared to a simple rod, installed under the same conditions.

Church made up of 2 spiers: IONIFLASH MACH® NG installed equidistant opposite the Simple Rod (sized as defined in standard NFC 17-102). T

he DIGICOUNT® counters records events.

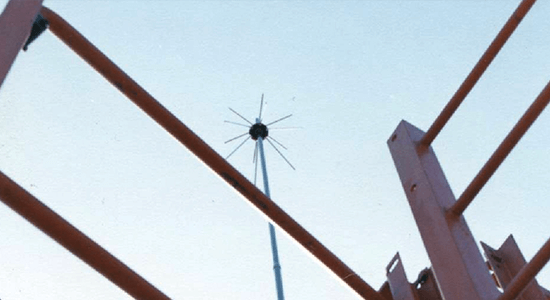

IN SITU TEST FRANCE TELECOM SITE PUYBEAUBIER – 1988

70 m radio pylon on a very lightning struck site: Installation of the IONIFLASH ESE and a 3 m single rod lightning rod and at a common height of 4.30 m at the top of the pylon.

Results noted by France Telecom:

• Several impacts on the IONIFLASH.

• 0 impact on the Single Rod Lightning Rod