RESEARCH AND DEVELOPMENT

PERMANENTS TEST,

GUARANTORS OF OUR RELIABILITY

LABORATORY TEST

The E.S.E. air terminals IONIFLASH MACH® passed with success the complete sequence of tests and last requirements of the NF C 17-102 standard (ed. 2011).

Some tests have even been carried out more strictly and more restrictive, in order to ensure a higher reliability to our products.

THE TEST SEQUENCE ENABLES TO CHECK IONIFLASH MACH® THROUGH SEVERAL CLIMATICAL CONDITIONS

General Tests :

Engraving process on the sphere of the IONIFLASH MACH®, to answer the marking requirements. It is indelible in time.

Mechanical Tests :

The continuous axis of the ESE IONIFLASH MACH® through which the lightning current passes, presents a minimal section of 200 mm 2, according to the requirements of this tests.

Environmental Tests :

The IONIFLASH MACH® have passed the environmental tests: – Salt mist treatment with a severity of level 2 according to the EN 60068-2-52. – Humid sulphurous treatment with a 7 cycles sequence according to the EN ISO 6988.

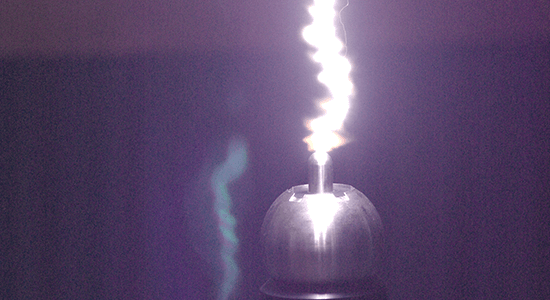

Electrical tests :

The IONIFLASH MACH®, range has been tested in lightning attachment impact with a 10/350 μs waveform at 100 kA and passes the test requirements.

Indeed, the IONIFLASH MACH® has been impacted by 2 series of 7 impacts at 100kA (while the standard requires only 3 impacts), one in negative polarity and one in positive polarity. The air-terminals show no deterioration or performing, except the parts through which the current is flowing, where tracks of initiating and fusion appear.

Efficiency tests :

Le ESE IONIFLASH MACH® is design to reduce the average statistical time associated with the initiating of the upward streamer. This ESE presents an advanced time in comparison with a simple reference rod (PTS) tested in the same conditions. This gain is evaluated in high voltage laboratory

IN CONFORMITY WITH NATIONAL STANDARDS / INTERNATIONAL STANDARDS / HOMOLOGATED IN CNRS LABORATORY

[smls id=”5576″]

IN SITU TESTS

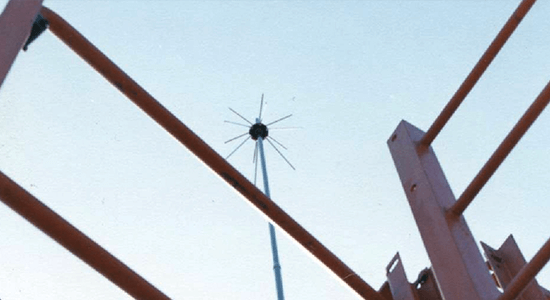

IN SITU TEST / HIGH MOUNTAIN RESORT – ALT. 1804M – APRIL 2009

The target: to validate the performance of the material used, as well as the behaviour of the IONIFLASH MACH® in extreme climatic conditions. Winds > 150km/h and temperatures from -35°C to 40°C Installation on a telecommunication pylon (15m high). The mechanical resistance and in temperature of materials in extreme climatic conditions is perfect. The lightning strike counter I FLASH REPORT® records the events

IN SITU TEST / SATU MARE CHURCH (ROMANIA) – JUNE 2011

The target: to observe the target: to observe the early streamer emission of the IONIFLASH MACH® facing a simple rod both installed in the same conditions. The church has two spires: the IONIFLASH MACH® and the simple rod are installed in

identical conditions. The lightning strike counter IONICOUNT® records the events

IN SITU TEST FRANCE TELECOM / PUY BEAUBIER SITE – ALT. 879M – JUNE 1987 TO JUNE 1988

Hertzian pylon of 70m installed on very impacted site. The IONIFLASH IF1 and a simple rod were installed at both side of the pylon at the same high. The results were several impacts on the IONIFLASH and none on the Simple rod.

SEE MORE…

STANDARD EXPERTISE

SCIENTIFIC ACTIONS